- Home Page

- Company Profile

-

Our Products

- Smart Soldering Machine

- Full Automatic Usb Soldering Machine

- Soldering Machine

- Laser Engraving Machine

- Laser Welding Machine

- Stainless Steel Automatic Laser Welding Machine

- Jewelry Laser Welding Machine with CCD

- Abrasive Laser Welding Machine

- 600W Laser Welding Machine

- Necklace Laser Welding Machine

- Jewelry Laser Spot Welding Machine

- 1500w Portable Fiber Laser Welding Machine for metal Handheld Laser Welders

- Customized Max 1500w laser welder automatic 3 axis sensors watches laser welding machine for aluminum nickel copper

- Laser welding machine laser welding machine Battery welding 1500w 2000w for metal stainless steel carbon steel

- Cable Testing Machine

- Power Cord Plug Cable Tester

- Universal Cable Harness Cable Tester

- CO2 Laser Marking Machine

- Crane Jib Laser Welding Machine

- Plug Wire Bending Testing Machine

- Inserting and Pulling Force Tester

- Tensile Test Machine

- Semi-Auto O-Ring Assembly Machine

- Factory Wholesale Semi-automatic Screw Feeder Screw Feeding Feeding Arrangement Machine Compact Hand Operated Screw Feeder

- Factory price 350A 64pins 128pins high voltage insulation testing cable tester precision four-wire cable testing machine

- 1kN 2kN 5kN 10kN Universal Material Constant Pull Force Tensile Testing Machine Computer Control Start and Analysis Machine

- Wire Color Sequence Continuity Tester

- High quality insert tester machine plug double head power cord cable testing

- Cross section analyser

- Wire terminal Tensile tester 50kgs

- face mask

- High Protective 3 layer non-woven fabrics ear loop disposable protective face mask

- Seal Laser Marking Machine

- Uv Laser Marking Machine

- Laser Marking Machine

- Portable Jewellery Laser Marking Machine

- Stainless Steel Laser Marking Machine

- Logo Laser Marking Machine

- Automatic Door Laser Marking Machine

- Disposable KN95 N95 face mask anti-virus mask

- Cable Winding and Binding Machine

- Fully Automatic Winding and Binding Machine

- Cable Winding and Binding Machine

- automatic winding and binding machine for cable

- Flat Wire Coiling and binding Machine for Electronic Components Production

- Automatic Flat Wire Winding and Binding Machine for Industrial Applications

- Automatic High Torque Wire Winding Machine for Large Transformers and Inductors

- Automatic Tape Wrapping Machine for Wire Harness, Alternative to Komax & Schleuniger

- Cutting and Stripping Machine

- Cable Stripping Machine

- Automatic Multi-core Cable Cutting and Stripping Machine

- Factory price automatic scrap copper wire stripping machine stripper

- Automatic Hose Pipe And Cable Cutting Machine

- Automatic Copper Wire Steel Wire Cutting Machine

- Enameled Copper Wire Stripper Wire Enamel Varnish Remover

- 0.8~6.99MM wire cutting stripping machine for coaxial cable

- Cable Stripping Machine

- Cable Stripping Machine

- Wire Stripping Machine

- cutting and stripping machine

- Machine Stripping Wire

- Customized copper wire cable recycling machine with high quality and best price

- automatic wire cutting and stripping machine

- double skin hot peeling machine wire stripping machine

- automatic electrical wire cutting stripping twisting machine

- Automatic Round Sheathed Two-core Cable Cutting and Stripping Machine

- Semi-automatic MI Cable Rotary Stripping Machine Suitable Diameter 1.5-10mm

- Electric Heating Tube Packed Hard Mineral Powder Loosen Shaking Removing Machine for MI Cable

- Automatic Computerized Tape Cutting Machine for Webbing Hook Loop Tape Plastic Zipper

- Automatic Waterproof Plug Stripping and Crimping Machine, 1500pcs/h for Auto Wire

- Fully Automatic Wire Stripping Machine for New Energy Vehicle Cables

- Electronic wire SAS stripping machine Wire and cable sheath off-line wire stripping machine

- Half stripping wire twisting machine

- High Precision Electric wire stripping machine

- Laser stripping the aluminum foil of cable

- crimping machine for terminal

- Cost-effective Semi-auto wire sealing station waterproof wire seal inserting machine

- large square servo cable crimping machine for big electric car cable

- Cable Wire Terminal Stripping Crimping Machine

- semi automatic wire terminal crimping machine

- Mobile Shaftless Pay-off Machine for Wire/Cable | Auto-Lifting & Servo Drive

- Fully Automatic Single-Head Terminal Machine with Twisting and Tin Dipping

- Full Automatic Double Head Wire Cutting Stripping Crimping Machine

- Automatic Power Cord Cutting Stripping Crimping Machine

- Dual-Station Fully Automatic Waterproof Plug Insertion Machine, 3s/Pcs, 98% Yield, for Wire Harness Assembly

- Factory price sale Coaxial wire ipex termination coax cable crimping machine

- SR-6B2 Electrical Crimping Tools Automatic Wire Crimping Machine

- Semi-Automatic cable waterproof plug sealing inserting machine

- 2T European Type Terminal Crimping Machine

- High-performance hand compact light wire terminal tube 6-120mm Cable Lug Pneumatic Crimping tool Machine

- Pneumatic terminal crimping machine

- Semi Automatic wire stripping crimping mute terminal crimping machine

- 2-10P Crystal Head Connector Crimping Machine Rj45 Crimping Machine Network Cable Making Machine

- Ferrule terminal crimping machine 0.3-6mm2

- Terminal crimping machine with vibration plate 2T

- High-Precision Aviation Terminal Crimper with Waterproof Plug Insertion System

- 0.5-16sqmm Pre-insulated tubular terminal servo crimping machine

- High-Speed Multi-Wire Cutting Stripping and Terminal Crimping Machine

- waterproof wire seal inserting machine

- SSD

- 120 GB 240GB 500GB 1tb 2tb 4 Tb SSD 2.5 Inch SATA Internal Solid State Drives 2.5 SSD

- Internal SSD 120GB 2.5inch SATA Hard Disk 240GB 480GB Backup Data

- SATA3 Laptop Desktop Solid State Drive Sp580 120 GB SATA 6GB/S 2.5in SSD

- SATA3 SSD Hard Disk 60GB 120GB 240GB 128GB 256GB 480GB 512GB 2.5" Internal Solid State Drive for Desktop PC Laptop

- Contact Us

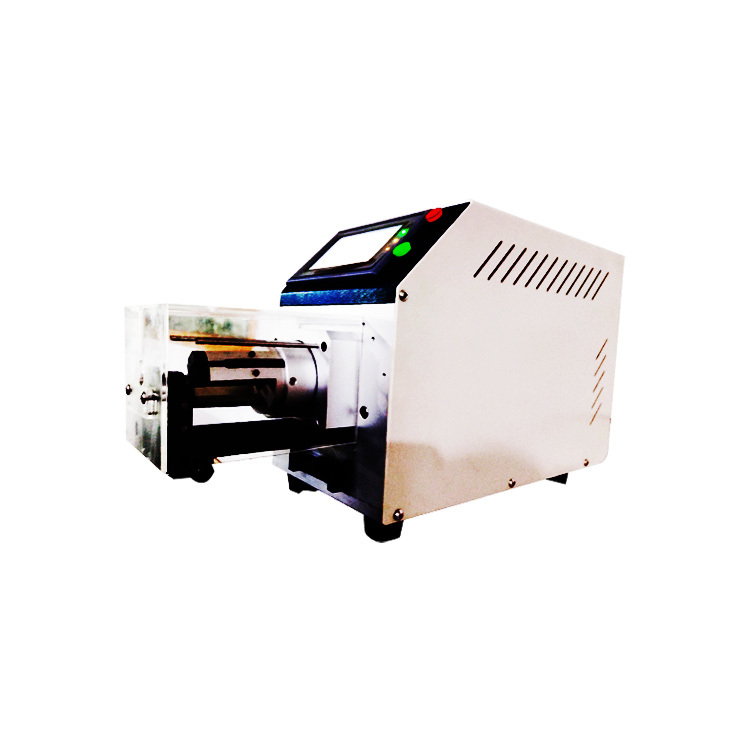

Cable Stripping Machine

790 USD ($)

Product Details:

- Product Type Cable Stripping Machine

- General Use cable stripping, wire stripping

- Material Mild Steel (MS)

- Capacity 150-200 kg/hr

- Weight (kg) 35kg Kilograms (kg)

- Cable Type Copper, Aluminium, PVC Cables

- Computerized No

- Click to view more

X

Cable Stripping Machine Price And Quantity

- 1 Set

- 790 USD ($)

- Alloy Steel

- PVC, Rubber, Teflon

- 35 meters/minute

- 50 Hz

- 11

- Emergency Stop, Guard Cover

- Low

Cable Stripping Machine Product Specifications

- Semi Automatic

- Green, Orange

- 150-200 kg/hr

- Manual

- No

- 600mm x 550mm x 900mm

- Copper, Aluminium, PVC Cables

- 35kg Kilograms (kg)

- 1.5 kW (Approx.)

- Cable Stripping Machine

- High efficiency, Low maintenance

- Mild Steel (MS)

- 1mm - 40mm

- cable stripping, wire stripping

- No

- 220V - 380V

- Alloy Steel

- PVC, Rubber, Teflon

- 35 meters/minute

- 50 Hz

- 11

- Emergency Stop, Guard Cover

- Low

Cable Stripping Machine Trade Information

- Shenzhen

- 7 Days

- Yes

- Contact us for information regarding our sample policy

Product Description

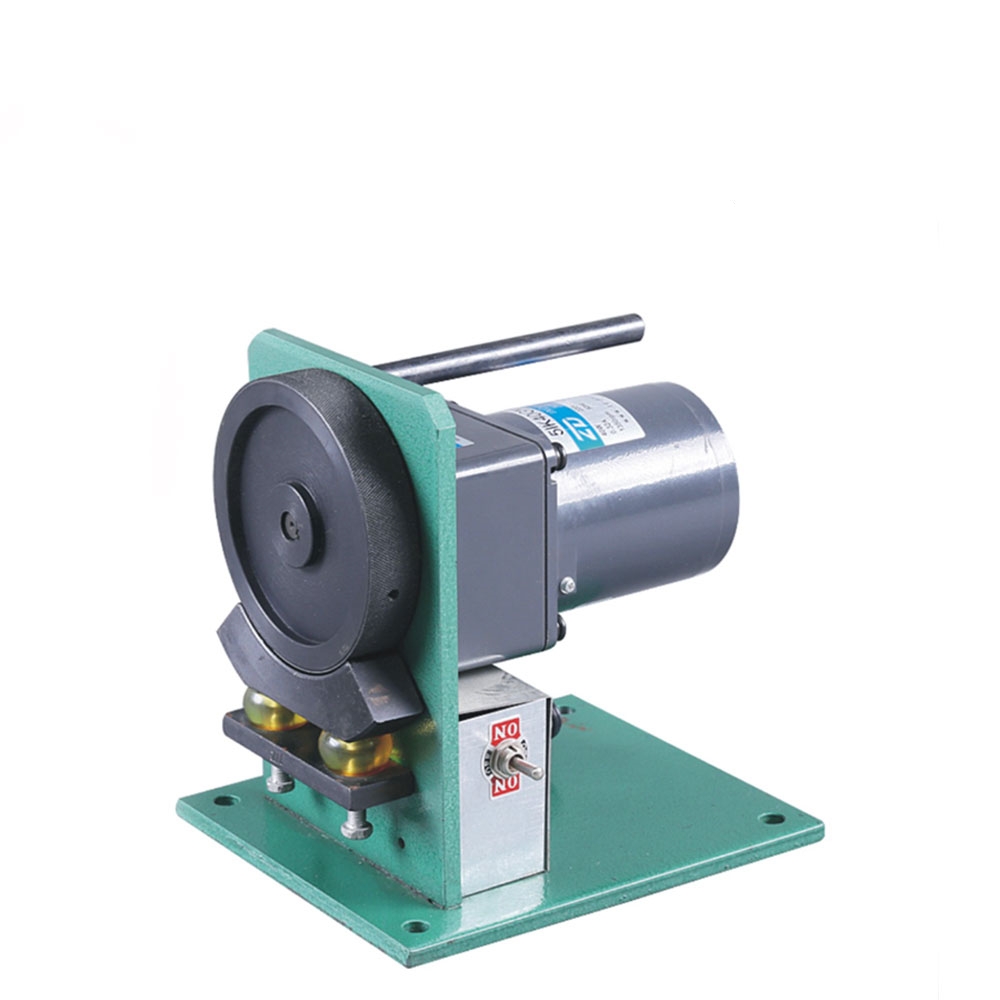

A cable stripping machine is a tool used to remove the insulation or outer sheath of electrical cables or wires. The machine consists of a cutting blade and two rollers, which feed the cable through the blade to strip away the insulation.There are different types of cable stripping machines available, ranging from manual to automatic models. Manual machines require the user to feed the cable through the blade manually, while automatic machines can process large volumes of cable automatically.Cable stripping machines are commonly used in recycling facilities or electrical contracting businesses to recycle or reuse copper wire, which is a valuable and in-demand material. Stripping the insulation from copper wire allows it to be easily recycled and resold.Using a cable stripping machine is a fast and efficient way to strip cables, saving time and increasing productivity. It also helps to reduce the risk of injury and fatigue associated with manual cable stripping.

Technical Specification

| Cutting length | 0.1 to 99999mm |

| Power supply | AC220V/50Hz |

| Stripping length | 0.1 to 99mm or customized for longer size |

| Motor power | 0.55kw |

| Twisting | optional |

| Available wire | AWG14 to AWG32 Support customized |

| Weight | 38kg |

High-Speed and Versatile Cable Stripping

This cable stripping machine delivers exceptional efficiency with a stripping speed of 35 meters per minute and accommodates cable diameters from 1mm to 40mm. Designed for versatility, it effectively processes copper, aluminum, and PVC cables, making it suitable for different industrial environments. The sturdy mild steel construction and alloy steel blades guarantee durability and long service life.

User-Friendly Operation and Safety Features

Equipped with 11 stripping holes and a semi-automatic system, the machine is both powerful and simple to use. Essential safety mechanisms such as an emergency stop button and guard cover provide a dependable working environment, minimizing risks for operators. Its low noise level further enhances workplace comfort.

FAQs of Cable Stripping Machine:

Q: How does the cable stripping machine handle different types of cable insulation?

A: The machine is designed to strip PVC, rubber, and Teflon cable insulation efficiently. Its robust alloy steel blades and adjustable stripping holes accommodate variations in insulation thickness and hardness, ensuring clean stripping results for each cable type.Q: What is the process for operating this semi-automatic cable stripping machine?

A: To operate, simply load the cable into the appropriate stripping hole that matches its diameter, power on the machine, and manually feed the cable through. The alloy steel blades will remove insulation at a speed of up to 35 meters per minute, and stripped cables can be collected at the output end.Q: When should regular maintenance be performed on this machine?

A: Routine maintenance is recommended after every 150200 kilograms of processed cable or at least once per week, depending on usage intensity. This includes cleaning the stripping holes, checking blade sharpness, lubricating moving parts, and inspecting safety features.Q: Where is this cable stripping machine most effectively used?

A: This machine is ideally suited for recycling plants, cable manufacturing workshops, and warehouses dealing with cable recovery. Its high capacity and adaptability make it valuable for both small-scale operations and larger industrial facilities.Q: What are the main benefits of using this cable stripping machine for wiring tasks?

A: Key benefits include high processing efficiency, low maintenance requirements, and the ability to handle a broad range of cable sizes and insulation types. The safety features and ease of use reduce operational risks while increasing productivity.Q: How does the manual pay-off system work with this machine?

A: Cables are manually fed into the machine, allowing precise control over input speed and alignment. This system supports operator flexibility and is well-suited for semi-automatic production environments without the need for advanced PLC control.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese