- Home Page

- Company Profile

-

Our Products

- Smart Soldering Machine

- Full Automatic Usb Soldering Machine

- Soldering Machine

- Laser Engraving Machine

- Laser Welding Machine

- Stainless Steel Automatic Laser Welding Machine

- Jewelry Laser Welding Machine with CCD

- Abrasive Laser Welding Machine

- 600W Laser Welding Machine

- Necklace Laser Welding Machine

- Jewelry Laser Spot Welding Machine

- 1500w Portable Fiber Laser Welding Machine for metal Handheld Laser Welders

- Customized Max 1500w laser welder automatic 3 axis sensors watches laser welding machine for aluminum nickel copper

- Laser welding machine laser welding machine Battery welding 1500w 2000w for metal stainless steel carbon steel

- Cable Testing Machine

- Power Cord Plug Cable Tester

- Universal Cable Harness Cable Tester

- CO2 Laser Marking Machine

- Crane Jib Laser Welding Machine

- Plug Wire Bending Testing Machine

- Inserting and Pulling Force Tester

- Tensile Test Machine

- Semi-Auto O-Ring Assembly Machine

- Factory Wholesale Semi-automatic Screw Feeder Screw Feeding Feeding Arrangement Machine Compact Hand Operated Screw Feeder

- Factory price 350A 64pins 128pins high voltage insulation testing cable tester precision four-wire cable testing machine

- 1kN 2kN 5kN 10kN Universal Material Constant Pull Force Tensile Testing Machine Computer Control Start and Analysis Machine

- Wire Color Sequence Continuity Tester

- High quality insert tester machine plug double head power cord cable testing

- Cross section analyser

- Wire terminal Tensile tester 50kgs

- face mask

- High Protective 3 layer non-woven fabrics ear loop disposable protective face mask

- Seal Laser Marking Machine

- Uv Laser Marking Machine

- Laser Marking Machine

- Portable Jewellery Laser Marking Machine

- Stainless Steel Laser Marking Machine

- Logo Laser Marking Machine

- Automatic Door Laser Marking Machine

- Disposable KN95 N95 face mask anti-virus mask

- Cable Winding and Binding Machine

- Fully Automatic Winding and Binding Machine

- Cable Winding and Binding Machine

- automatic winding and binding machine for cable

- Flat Wire Coiling and binding Machine for Electronic Components Production

- Automatic Flat Wire Winding and Binding Machine for Industrial Applications

- Automatic High Torque Wire Winding Machine for Large Transformers and Inductors

- Automatic Tape Wrapping Machine for Wire Harness, Alternative to Komax & Schleuniger

- Cutting and Stripping Machine

- Cable Stripping Machine

- Automatic Multi-core Cable Cutting and Stripping Machine

- Factory price automatic scrap copper wire stripping machine stripper

- Automatic Hose Pipe And Cable Cutting Machine

- Automatic Copper Wire Steel Wire Cutting Machine

- Enameled Copper Wire Stripper Wire Enamel Varnish Remover

- 0.8~6.99MM wire cutting stripping machine for coaxial cable

- Cable Stripping Machine

- Cable Stripping Machine

- Wire Stripping Machine

- cutting and stripping machine

- Machine Stripping Wire

- Customized copper wire cable recycling machine with high quality and best price

- automatic wire cutting and stripping machine

- double skin hot peeling machine wire stripping machine

- automatic electrical wire cutting stripping twisting machine

- Automatic Round Sheathed Two-core Cable Cutting and Stripping Machine

- Semi-automatic MI Cable Rotary Stripping Machine Suitable Diameter 1.5-10mm

- Electric Heating Tube Packed Hard Mineral Powder Loosen Shaking Removing Machine for MI Cable

- Automatic Computerized Tape Cutting Machine for Webbing Hook Loop Tape Plastic Zipper

- Automatic Waterproof Plug Stripping and Crimping Machine, 1500pcs/h for Auto Wire

- Fully Automatic Wire Stripping Machine for New Energy Vehicle Cables

- Electronic wire SAS stripping machine Wire and cable sheath off-line wire stripping machine

- Half stripping wire twisting machine

- High Precision Electric wire stripping machine

- Laser stripping the aluminum foil of cable

- crimping machine for terminal

- large square servo cable crimping machine for big electric car cable

- Cable Wire Terminal Stripping Crimping Machine

- Cost-effective Semi-auto wire sealing station waterproof wire seal inserting machine

- semi automatic wire terminal crimping machine

- Mobile Shaftless Pay-off Machine for Wire/Cable | Auto-Lifting & Servo Drive

- Fully Automatic Single-Head Terminal Machine with Twisting and Tin Dipping

- Full Automatic Double Head Wire Cutting Stripping Crimping Machine

- Automatic Power Cord Cutting Stripping Crimping Machine

- Dual-Station Fully Automatic Waterproof Plug Insertion Machine, 3s/Pcs, 98% Yield, for Wire Harness Assembly

- Factory price sale Coaxial wire ipex termination coax cable crimping machine

- SR-6B2 Electrical Crimping Tools Automatic Wire Crimping Machine

- Semi-Automatic cable waterproof plug sealing inserting machine

- 2T European Type Terminal Crimping Machine

- High-performance hand compact light wire terminal tube 6-120mm Cable Lug Pneumatic Crimping tool Machine

- Pneumatic terminal crimping machine

- Semi Automatic wire stripping crimping mute terminal crimping machine

- 2-10P Crystal Head Connector Crimping Machine Rj45 Crimping Machine Network Cable Making Machine

- Ferrule terminal crimping machine 0.3-6mm2

- Terminal crimping machine with vibration plate 2T

- High-Precision Aviation Terminal Crimper with Waterproof Plug Insertion System

- waterproof wire seal inserting machine

- SSD

- 120 GB 240GB 500GB 1tb 2tb 4 Tb SSD 2.5 Inch SATA Internal Solid State Drives 2.5 SSD

- Internal SSD 120GB 2.5inch SATA Hard Disk 240GB 480GB Backup Data

- SATA3 Laptop Desktop Solid State Drive Sp580 120 GB SATA 6GB/S 2.5in SSD

- SATA3 SSD Hard Disk 60GB 120GB 240GB 128GB 256GB 480GB 512GB 2.5" Internal Solid State Drive for Desktop PC Laptop

- Contact Us

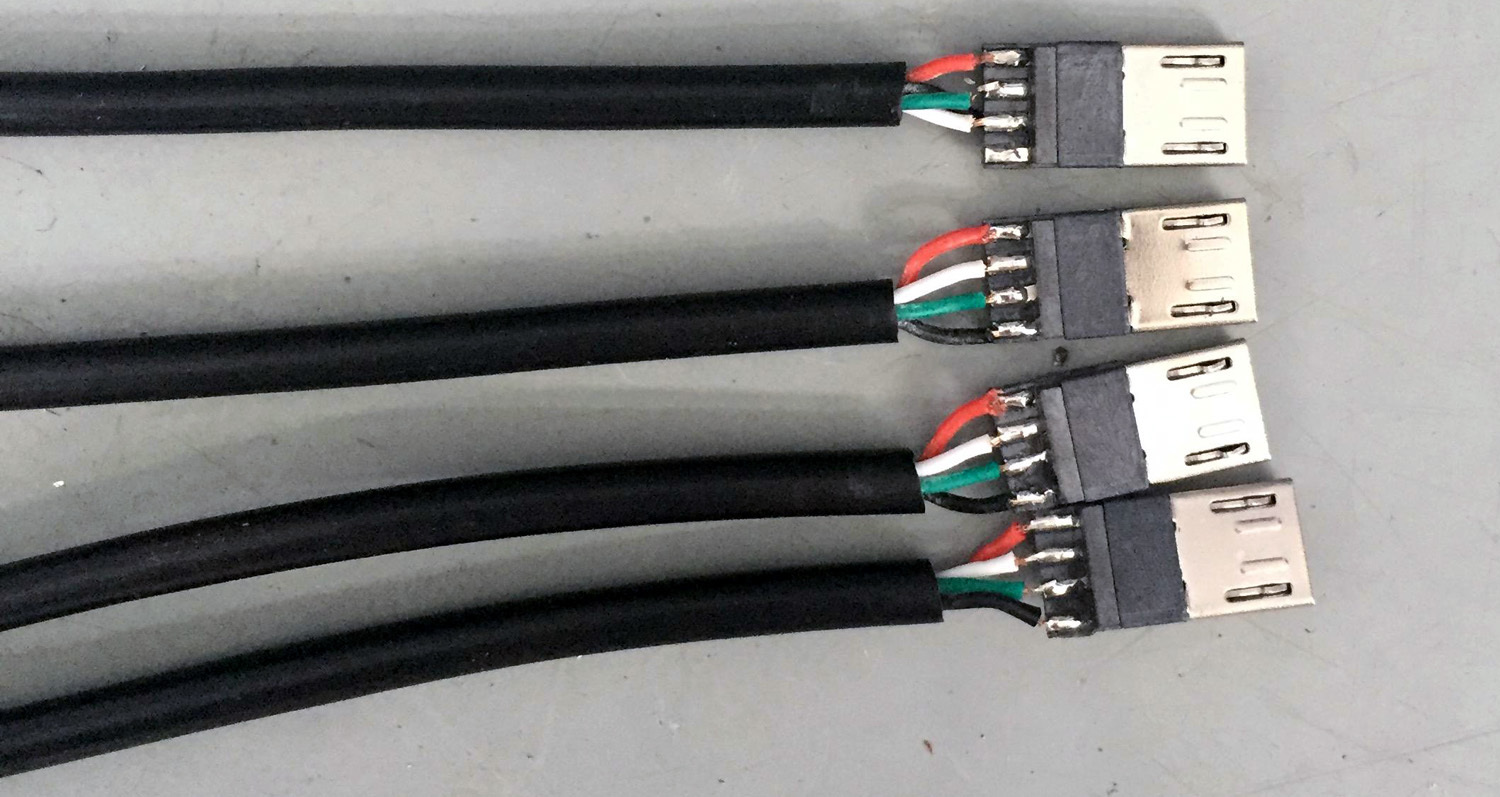

Universal Cable Harness Cable Tester

960.0 USD ($)/Unit

Product Details:

- Features Digital display, buzzer alarm, portable, user-programmable

- Load Capacity Up to 128 wires (dep. on model) Pound (lb)

- Power AC 220V Volt (v)

- Dimension (L*W*H) 410 x 330 x 120 mm Millimeter (mm)

- Resolution 1 wire signal

- Frequency 50/60Hz Hertz (HZ)

- Power Source Electric

- Click to view more

X

Universal Cable Harness Cable Tester Price And Quantity

- N/A (Non-destructive tester)

- N/A (electrical test only)

- 1 ,

- 960.0 USD ($)/Unit

Universal Cable Harness Cable Tester Product Specifications

- Powder-coated metal, ABS panel

- 99.9% detection rate %

- Single Phase

- AC 220V Volt (v)

- Microprocessor based

- Multiple harnesses at once Pcs/hr

- 410 x 330 x 120 mm Millimeter (mm)

- Grey

- Digital display, buzzer alarm, portable, user-programmable

- Up to 128 wires (dep. on model) Pound (lb)

- <30W Watt (W)

- Fast scanning (1 sec/test approx.) mm/s

- 220V AC Volt (v)

- 0 C to 50 C Planck temperature ()

- Electric

- Manual & Automatic Modes

- Continuity, Short, and Open Circuit Sensors

- Testing wire harnesses, cables, connectors

- Approx. 5 kg Kilograms (kg)

- 50/60Hz Hertz (HZ)

- 1 wire signal

- Universal Cable Harness Cable Tester

Product Description

Specification

Advanced Functions Programmable sequence tests Auto Searching Self Diagnosis Self Reset

Scanning Mode AutoManual Switchable

Measurement Signal 5Vdc

Output Rating 5Vdc12Vdc

DC Hipot 512Vdc

AC Hipot 512Vac

DisplayAlarm 320x240 dpi graphic LED display PassFail LEDScreen DisplayAlarm

Measurement Connection 1024Test Pointsfor Optional

Hipot Calibration Output

Auto Pin Search Jack

Front Panel Button Sys keyFast keyEdit keyfunction Key

Interface RS232 Port Printer Port Remote Control Port

Power Supply 115230 VAC 10 6050Hz

Accessories Remote Control Cable Optional RS232 Control Cable Optional Power Cord

Auto Pin Search Probe Fixture Cable Fixture Board Users Manual Test Report

Memory Content Max500 Files Settingfor Optional

4 M Inside SRAM USBPC Expansion

TemperatureHumidity 15C 35C RH75

Dimension WxHxD 400x175x220mm

NET Weight Around 12Kg Wo accessory

Cable Request Max 1mF

Feature

The system provides ChineseEnglish free switch operation interface

5V12 Vac Test Voltage

512 Max Test Points Max of all series

500 Max Files Memorysupport USB or PC unlimited expansion

Using Embedded Linux operating system

Adopted high resolution color 640480 TFT LCD

Large 320240 LCD display

Instant test time 060s optional adjustment

Providing SingleEnd Multisegment Standard and Spot test of wire

Auto Scan and Auto Pin Search

The system provides advanced instant opencircuit shortcircuit continuity test

Intermittent Conductance Test

Intermittent OpenShort Test

Full Programming Sequence Test

Versatile IO Ports for application

Statistics and Print Function

Provide REMOTE interface communicate with PLD auto test fixture

Provide personalized customization according to different requirements

Efficient and Accurate Cable Testing

Experience reliable detection of open short and missed lines with a 999 accuracy rate and testing time of just 12 seconds per harness The Universal Cable Harness Cable Testers advanced microprocessor control ensures fast and consistent results ideal for highoutput manufacturing and quality assurance settings

Versatile Compatibility and Customization

This cable tester supports multiple cable types including flat round multicore and custom harnesses With customizable test probes and fixtures users can adapt the tester to various cable specifications The device is designed to meet the needs of distributors manufacturers exporters and suppliers

UserFriendly Interface and Data Management

Equipped with an intuitive membrane keypad and pushbutton controls the tester is simple to operate The digital LCD screen displays test outcomes clearly and the machine supports test program storage for efficient repeat testing and batch processing Language options are available to accommodate different users

FAQs of Universal Cable Harness Cable Tester

Q How does the Universal Cable Harness Cable Tester detect faults in cables

A The tester uses advanced continuity short and open circuit sensors providing both visual and audible alerts for detected open lines shorts or missed connections Results are displayed on the LCD digital screen and users receive an immediate buzzer notification for faults

Q What types of cables can be tested with this device

A It supports flat round multicore and customized wire harnesses Customizable test probes and fixtures allow adaptation to different connector types making it suitable for diverse cable configurations in manufacturing and export settings

Q When should I use the fully automatic scan mode versus the manual single test mode

A Use manual single test mode for individual harnesses troubleshooting or oneoff checks The fully automatic scan mode is best for batch testing highvolume production or when you need consistent and rapid evaluation of multiple harnesses

Q Where can I utilize this cable tester for optimal results

A The tester is ideal for use in manufacturing plants electronic assembly lines quality control labs and export inspection facilities Its CE certification ensures safe operation in professional environments

Q What is the process for storing and recalling test programs on the device

A Users can create save and recall test programs through the membrane keypad interface This feature allows quick setup for repeated tests improving efficiency in batch testing or frequent production runs

Q How does the tester benefit users working with multiple harnesses

A With the capacity to test multiple harnesses simultaneously and support for up to 128 wires depending on the model the tester streamlines quality control reduces labor time and enhances accuracy for manufacturers suppliers and exporters

Q What are the main safety and compliance features of the product

A The cable tester is CE marked operates on a safe AC 220V supply with less than 30W power consumption and uses powdercoated metal and ABS panel for durability It complies with international safety standards ensuring reliable operation in industrial environments

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese