- Home Page

- Company Profile

-

Our Products

- Smart Soldering Machine

- Full Automatic Usb Soldering Machine

- Soldering Machine

- Laser Engraving Machine

- Laser Welding Machine

- Stainless Steel Automatic Laser Welding Machine

- Jewelry Laser Welding Machine with CCD

- Abrasive Laser Welding Machine

- 600W Laser Welding Machine

- Necklace Laser Welding Machine

- Jewelry Laser Spot Welding Machine

- 1500w Portable Fiber Laser Welding Machine for metal Handheld Laser Welders

- Customized Max 1500w laser welder automatic 3 axis sensors watches laser welding machine for aluminum nickel copper

- Laser welding machine laser welding machine Battery welding 1500w 2000w for metal stainless steel carbon steel

- Cable Testing Machine

- Power Cord Plug Cable Tester

- Universal Cable Harness Cable Tester

- CO2 Laser Marking Machine

- Crane Jib Laser Welding Machine

- Plug Wire Bending Testing Machine

- Inserting and Pulling Force Tester

- Tensile Test Machine

- Semi-Auto O-Ring Assembly Machine

- Factory Wholesale Semi-automatic Screw Feeder Screw Feeding Feeding Arrangement Machine Compact Hand Operated Screw Feeder

- Factory price 350A 64pins 128pins high voltage insulation testing cable tester precision four-wire cable testing machine

- 1kN 2kN 5kN 10kN Universal Material Constant Pull Force Tensile Testing Machine Computer Control Start and Analysis Machine

- Wire Color Sequence Continuity Tester

- High quality insert tester machine plug double head power cord cable testing

- Cross section analyser

- Wire terminal Tensile tester 50kgs

- face mask

- High Protective 3 layer non-woven fabrics ear loop disposable protective face mask

- Seal Laser Marking Machine

- Uv Laser Marking Machine

- Laser Marking Machine

- Portable Jewellery Laser Marking Machine

- Stainless Steel Laser Marking Machine

- Logo Laser Marking Machine

- Automatic Door Laser Marking Machine

- Disposable KN95 N95 face mask anti-virus mask

- Cable Winding and Binding Machine

- Fully Automatic Winding and Binding Machine

- Cable Winding and Binding Machine

- automatic winding and binding machine for cable

- Flat Wire Coiling and binding Machine for Electronic Components Production

- Automatic Flat Wire Winding and Binding Machine for Industrial Applications

- Automatic High Torque Wire Winding Machine for Large Transformers and Inductors

- Automatic Tape Wrapping Machine for Wire Harness, Alternative to Komax & Schleuniger

- Cutting and Stripping Machine

- Cable Stripping Machine

- Automatic Multi-core Cable Cutting and Stripping Machine

- Factory price automatic scrap copper wire stripping machine stripper

- Automatic Hose Pipe And Cable Cutting Machine

- Automatic Copper Wire Steel Wire Cutting Machine

- Enameled Copper Wire Stripper Wire Enamel Varnish Remover

- 0.8~6.99MM wire cutting stripping machine for coaxial cable

- Cable Stripping Machine

- Cable Stripping Machine

- Wire Stripping Machine

- cutting and stripping machine

- Machine Stripping Wire

- Customized copper wire cable recycling machine with high quality and best price

- automatic wire cutting and stripping machine

- double skin hot peeling machine wire stripping machine

- automatic electrical wire cutting stripping twisting machine

- Automatic Round Sheathed Two-core Cable Cutting and Stripping Machine

- Semi-automatic MI Cable Rotary Stripping Machine Suitable Diameter 1.5-10mm

- Electric Heating Tube Packed Hard Mineral Powder Loosen Shaking Removing Machine for MI Cable

- Automatic Computerized Tape Cutting Machine for Webbing Hook Loop Tape Plastic Zipper

- Automatic Waterproof Plug Stripping and Crimping Machine, 1500pcs/h for Auto Wire

- Fully Automatic Wire Stripping Machine for New Energy Vehicle Cables

- Electronic wire SAS stripping machine Wire and cable sheath off-line wire stripping machine

- Half stripping wire twisting machine

- High Precision Electric wire stripping machine

- Laser stripping the aluminum foil of cable

- crimping machine for terminal

- Cost-effective Semi-auto wire sealing station waterproof wire seal inserting machine

- large square servo cable crimping machine for big electric car cable

- Cable Wire Terminal Stripping Crimping Machine

- semi automatic wire terminal crimping machine

- Mobile Shaftless Pay-off Machine for Wire/Cable | Auto-Lifting & Servo Drive

- Fully Automatic Single-Head Terminal Machine with Twisting and Tin Dipping

- Full Automatic Double Head Wire Cutting Stripping Crimping Machine

- Automatic Power Cord Cutting Stripping Crimping Machine

- Dual-Station Fully Automatic Waterproof Plug Insertion Machine, 3s/Pcs, 98% Yield, for Wire Harness Assembly

- Factory price sale Coaxial wire ipex termination coax cable crimping machine

- SR-6B2 Electrical Crimping Tools Automatic Wire Crimping Machine

- Semi-Automatic cable waterproof plug sealing inserting machine

- 2T European Type Terminal Crimping Machine

- High-performance hand compact light wire terminal tube 6-120mm Cable Lug Pneumatic Crimping tool Machine

- Pneumatic terminal crimping machine

- Semi Automatic wire stripping crimping mute terminal crimping machine

- 2-10P Crystal Head Connector Crimping Machine Rj45 Crimping Machine Network Cable Making Machine

- Ferrule terminal crimping machine 0.3-6mm2

- Terminal crimping machine with vibration plate 2T

- High-Precision Aviation Terminal Crimper with Waterproof Plug Insertion System

- 0.5-16sqmm Pre-insulated tubular terminal servo crimping machine

- High-Speed Multi-Wire Cutting Stripping and Terminal Crimping Machine

- waterproof wire seal inserting machine

- SSD

- 120 GB 240GB 500GB 1tb 2tb 4 Tb SSD 2.5 Inch SATA Internal Solid State Drives 2.5 SSD

- Internal SSD 120GB 2.5inch SATA Hard Disk 240GB 480GB Backup Data

- SATA3 Laptop Desktop Solid State Drive Sp580 120 GB SATA 6GB/S 2.5in SSD

- SATA3 SSD Hard Disk 60GB 120GB 240GB 128GB 256GB 480GB 512GB 2.5" Internal Solid State Drive for Desktop PC Laptop

- Contact Us

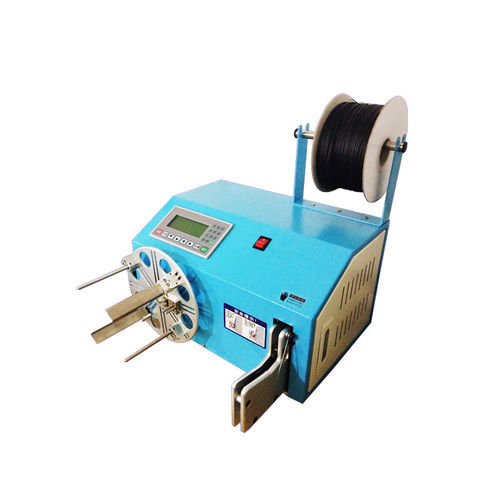

Fully Automatic Winding and Binding Machine

4999.0 USD ($)/Unit

Product Details:

- Product Type Fully Automatic Winding and Binding Machine

- General Use Cable Winding and Binding Automation

- Material High-grade MS & SS construction

- Weight (kg) Approx. 800 kg Kilograms (kg)

- Computerized Yes

- Voltage 220V/380V, 50Hz Volt (v)

- Cable Diameter 2 mm - 14 mm Millimeter (mm)

- Click to view more

X

Fully Automatic Winding and Binding Machine Price And Quantity

- 4999.0 USD ($)/Unit

- 1 Unit

- Automatic error alarm and self-diagnosis

- Storage of multiple winding programs

- CE certified safety guards and emergency stop

- Below 70 dB(A)

- Level foundation, 2.5 m installation clearance

- Temperature: 5C40C, Humidity: 85% RH

- Required, 0.5-0.7 MPa compressed air

- 80 mm to 240 mm

- 5-15 bundles/min (depending on cable and bundle size)

- Programmable, 1 m to 50 m

- Ergonomic color touch screen HMI

- Automatic twisted or tape binding selectable

Fully Automatic Winding and Binding Machine Product Specifications

- Cable Winding and Binding Automation

- Approx. 800 kg Kilograms (kg)

- Yes

- Industrial Blue & Grey

- 2 mm - 14 mm Millimeter (mm)

- 220V/380V, 50Hz Volt (v)

- Fully Automatic Winding and Binding Machine

- High-grade MS & SS construction

- Auto coil length adjustment, Overload protection, Safety enclosure

- 2550mm x 1300mm x 1850mm Millimeter (mm)

- Automatic error alarm and self-diagnosis

- Storage of multiple winding programs

- CE certified safety guards and emergency stop

- Below 70 dB(A)

- Level foundation, 2.5 m installation clearance

- Temperature: 5C40C, Humidity: 85% RH

- Required, 0.5-0.7 MPa compressed air

- 80 mm to 240 mm

- 5-15 bundles/min (depending on cable and bundle size)

- Programmable, 1 m to 50 m

- Ergonomic color touch screen HMI

- Automatic twisted or tape binding selectable

Fully Automatic Winding and Binding Machine Trade Information

- shenzhen

- Cash on Delivery (COD), Delivery Point (DP), Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Western Union, Paypal, Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Days after Acceptance (DA), Cash in Advance (CID), Cheque, Cash Advance (CA)

- 500 Unit Per Month

- 15 Days

- Yes

- Free samples are available

- North America, Central America, Asia, Africa

- All India

Product Description

Specification

Apply to cable length 04m5m

Head 080mm and the end 0250mmadjustable

other request can be customized

Apply to the cable of OD 15mmOD 80mm

Cable outline round oblate winding

wire spacing sizeafter binding60180 mm adjustable

Coil number Adjustable

Production efficiency Max AC 1800HDC 1900H

Control Screen 7 inches imported touch screen

Power consumption25KW

Air pressure 6 kgf

Voltage 220 VCA 12A 5060HZ

Weight280KG

Dimensionmm138L58W155Hcm

SafeguardAgainst leakage short circuit overheat

Feature

1The system provide ChineseEnglish free switch 7inch imported touch screen operation Setting the data as clients required easy operate

2Suitable for many kinds of cables and binding style Singleend doubleends 8 shape circle shape AC power cord DC power cord video line HDMI cable USB cable and so on

3Full Auto and fast binding by Step on foot switch

4Save labor cost and improved output

5Adopted PLC program control 7 inch touch screen for setting parameters

6Provide personalized customization base on different requirements

7Wire lengthHead length Tail length Total binding lengthcoil number speed quantity can be set

Advanced Winding Binding Technology

This fully automatic machine offers unrivaled customization with selectable twisted or tape binding Integrated PLC control and servodriven payoff enable accurate highspeed operation for various cable types achieving up to 1200 coils every eight hours Adaptable to cables from 2 mm to 14 mm in diameter it ensures consistent highquality bundling for power signal and data cables

UserFriendly and Safe Operation

Featuring an ergonomic color touch screen interface this machine is designed for easy setup and operation CEcertified safety guards and an intuitive emergency stop safeguard operators while the automatic error alarm and selfdiagnostic function enable prompt identification and correction of issues minimizing downtime and maximizing productivity

Flexible Installation and Durable Construction

Built with highgrade MS and SS materials the machine is engineered for durability and performance It requires a level foundation and 25 meters of clearance for installation Suitable for variable environments 5C40C 85 RH it maintains quiet operation below 70 dBA making it ideal for modern industrial settings

FAQs of Fully Automatic Winding and Binding Machine

Q How does the automatic winding and binding process work on this machine

A The machine automatically winds cables to programmed lengths and binds each coil using either twisted wire or tape depending on your selection All functions are managed via the PLCcontrolled system delivering precise and consistent bundles every cycle

Q What types of cables can this machine handle

A This system accommodates a variety of cables including power cables data cables signal lines and multicore cables with diameters from 2 mm up to 14 mm Its suitable for applications in industrial manufacturing electronics and more

Q When should the memory function be used

A The memory function is ideal for storing winding and binding programs used regularly This allows operators to quickly recall parameters for different cable types and sizes streamlining setup and reducing changeover times

Q Where should the machine be installed for optimal performance

A Install the machine on a level foundation with at least 25 meters of installation clearance in an environment with a temperature range of 5C to 40C and relative humidity up to 85 This setup ensures safe and efficient operation

Q What is the process if an error occurs during operation

A If an error is detected the systems selfdiagnosis and automatic alarm feature will notify the operator through the HMI Operators can review error messages follow recommended troubleshooting steps and resume production safely after resolving the issue

Q How does automatic coil length adjustment benefit production

A Programmable coil lengths from 1 to 50 meters allow precise customization for different customer requirements reduce material waste and enhance production efficiency by ensuring each bundle meets exact specifications

Q What maintenance or utility inputs are required for operation

A The machine requires a compressed air supply 0507 MPa and operates on a 220V380V 50Hz power connection Routine maintenance involves checking moving parts safety guards and cleaning the enclosure ensuring reliable and safe longterm performance

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese