- Home Page

- Company Profile

-

Our Products

- Smart Soldering Machine

- Full Automatic Usb Soldering Machine

- Soldering Machine

- Laser Engraving Machine

- Laser Welding Machine

- Stainless Steel Automatic Laser Welding Machine

- Jewelry Laser Welding Machine with CCD

- Abrasive Laser Welding Machine

- 600W Laser Welding Machine

- Necklace Laser Welding Machine

- Jewelry Laser Spot Welding Machine

- 1500w Portable Fiber Laser Welding Machine for metal Handheld Laser Welders

- Customized Max 1500w laser welder automatic 3 axis sensors watches laser welding machine for aluminum nickel copper

- Laser welding machine laser welding machine Battery welding 1500w 2000w for metal stainless steel carbon steel

- Cable Testing Machine

- Power Cord Plug Cable Tester

- Universal Cable Harness Cable Tester

- CO2 Laser Marking Machine

- Crane Jib Laser Welding Machine

- Plug Wire Bending Testing Machine

- Inserting and Pulling Force Tester

- Tensile Test Machine

- Semi-Auto O-Ring Assembly Machine

- Factory Wholesale Semi-automatic Screw Feeder Screw Feeding Feeding Arrangement Machine Compact Hand Operated Screw Feeder

- Factory price 350A 64pins 128pins high voltage insulation testing cable tester precision four-wire cable testing machine

- 1kN 2kN 5kN 10kN Universal Material Constant Pull Force Tensile Testing Machine Computer Control Start and Analysis Machine

- Wire Color Sequence Continuity Tester

- High quality insert tester machine plug double head power cord cable testing

- Cross section analyser

- Wire terminal Tensile tester 50kgs

- face mask

- High Protective 3 layer non-woven fabrics ear loop disposable protective face mask

- Seal Laser Marking Machine

- Uv Laser Marking Machine

- Laser Marking Machine

- Portable Jewellery Laser Marking Machine

- Stainless Steel Laser Marking Machine

- Logo Laser Marking Machine

- Automatic Door Laser Marking Machine

- Disposable KN95 N95 face mask anti-virus mask

- Cable Winding and Binding Machine

- Fully Automatic Winding and Binding Machine

- Cable Winding and Binding Machine

- automatic winding and binding machine for cable

- Flat Wire Coiling and binding Machine for Electronic Components Production

- Automatic Flat Wire Winding and Binding Machine for Industrial Applications

- Automatic High Torque Wire Winding Machine for Large Transformers and Inductors

- Automatic Tape Wrapping Machine for Wire Harness, Alternative to Komax & Schleuniger

- Cutting and Stripping Machine

- Cable Stripping Machine

- Automatic Multi-core Cable Cutting and Stripping Machine

- Factory price automatic scrap copper wire stripping machine stripper

- Automatic Hose Pipe And Cable Cutting Machine

- Automatic Copper Wire Steel Wire Cutting Machine

- Enameled Copper Wire Stripper Wire Enamel Varnish Remover

- 0.8~6.99MM wire cutting stripping machine for coaxial cable

- Cable Stripping Machine

- Cable Stripping Machine

- Wire Stripping Machine

- cutting and stripping machine

- Machine Stripping Wire

- Customized copper wire cable recycling machine with high quality and best price

- automatic wire cutting and stripping machine

- double skin hot peeling machine wire stripping machine

- automatic electrical wire cutting stripping twisting machine

- Automatic Round Sheathed Two-core Cable Cutting and Stripping Machine

- Semi-automatic MI Cable Rotary Stripping Machine Suitable Diameter 1.5-10mm

- Electric Heating Tube Packed Hard Mineral Powder Loosen Shaking Removing Machine for MI Cable

- Automatic Computerized Tape Cutting Machine for Webbing Hook Loop Tape Plastic Zipper

- Automatic Waterproof Plug Stripping and Crimping Machine, 1500pcs/h for Auto Wire

- Fully Automatic Wire Stripping Machine for New Energy Vehicle Cables

- Electronic wire SAS stripping machine Wire and cable sheath off-line wire stripping machine

- Half stripping wire twisting machine

- High Precision Electric wire stripping machine

- Laser stripping the aluminum foil of cable

- crimping machine for terminal

- Cost-effective Semi-auto wire sealing station waterproof wire seal inserting machine

- large square servo cable crimping machine for big electric car cable

- Cable Wire Terminal Stripping Crimping Machine

- semi automatic wire terminal crimping machine

- Mobile Shaftless Pay-off Machine for Wire/Cable | Auto-Lifting & Servo Drive

- Fully Automatic Single-Head Terminal Machine with Twisting and Tin Dipping

- Full Automatic Double Head Wire Cutting Stripping Crimping Machine

- Automatic Power Cord Cutting Stripping Crimping Machine

- Dual-Station Fully Automatic Waterproof Plug Insertion Machine, 3s/Pcs, 98% Yield, for Wire Harness Assembly

- Factory price sale Coaxial wire ipex termination coax cable crimping machine

- SR-6B2 Electrical Crimping Tools Automatic Wire Crimping Machine

- Semi-Automatic cable waterproof plug sealing inserting machine

- 2T European Type Terminal Crimping Machine

- High-performance hand compact light wire terminal tube 6-120mm Cable Lug Pneumatic Crimping tool Machine

- Pneumatic terminal crimping machine

- Semi Automatic wire stripping crimping mute terminal crimping machine

- 2-10P Crystal Head Connector Crimping Machine Rj45 Crimping Machine Network Cable Making Machine

- Ferrule terminal crimping machine 0.3-6mm2

- Terminal crimping machine with vibration plate 2T

- High-Precision Aviation Terminal Crimper with Waterproof Plug Insertion System

- 0.5-16sqmm Pre-insulated tubular terminal servo crimping machine

- High-Speed Multi-Wire Cutting Stripping and Terminal Crimping Machine

- waterproof wire seal inserting machine

- SSD

- 120 GB 240GB 500GB 1tb 2tb 4 Tb SSD 2.5 Inch SATA Internal Solid State Drives 2.5 SSD

- Internal SSD 120GB 2.5inch SATA Hard Disk 240GB 480GB Backup Data

- SATA3 Laptop Desktop Solid State Drive Sp580 120 GB SATA 6GB/S 2.5in SSD

- SATA3 SSD Hard Disk 60GB 120GB 240GB 128GB 256GB 480GB 512GB 2.5" Internal Solid State Drive for Desktop PC Laptop

- Contact Us

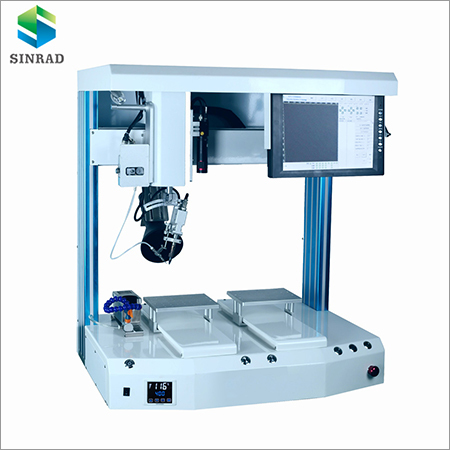

Smart Soldering Machine

5000 USD ($)/Set

Product Details:

- Composition Tin 60%, Lead 40%

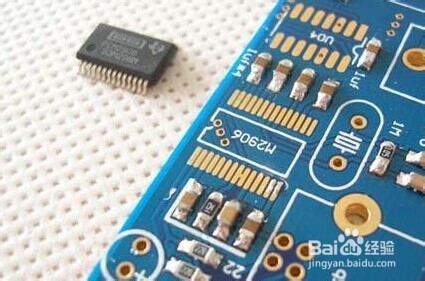

- Application PCB soldering, electronic circuit joining, component assembly

- Operating Voltage 220V AC

- Operating Temperature 150C to 450C

- Material High-grade stainless steel and industrial alloy

- Diameter 1.5 mm

- Flux Content 2.0%

- Click to view more

X

Smart Soldering Machine Price And Quantity

- 1 Set

- 4000.00 - 15000.00 USD ($)/Set

- 5000 USD ($)/Set

- 120 W

- Overheat protection, emergency stop switch

- Available

- 22 kg

- Microcontroller-based digital touchscreen panel

- 400 mm x 300 mm x 250 mm

- Up to 3 joints per second

- High-resolution LCD

- Programmable from 5 mm to 50 mm

Smart Soldering Machine Product Specifications

- Nickel Plating

- 150C to 450C

- 2.0%

- High-grade stainless steel and industrial alloy

- PCB soldering, electronic circuit joining, component assembly

- 220V AC

- 1.5 mm

- Tin 60%, Lead 40%

- 230C

- 120 W

- Overheat protection, emergency stop switch

- Available

- 22 kg

- Microcontroller-based digital touchscreen panel

- 400 mm x 300 mm x 250 mm

- Up to 3 joints per second

- High-resolution LCD

- Programmable from 5 mm to 50 mm

Smart Soldering Machine Trade Information

- 200 Set Per Month

- 15 Days

- Yes

- Free samples are available

- packed in wooden case

Product Description

We are well reckoned manufacturer of high performing Smart Soldering Machine in the market. Our offered machine is synonymous to control and stability as the most reliable mechanism is implied in this tool. The machine has high strength, deflection resistance and requires less effort to perform effectively. Our prestigious clients can avail this Smart Soldering Machine form us at the best price in the industry.

Features:

- Accurate efficient soldering

- Automatic operations

- Robust construction

As a trusted leading Manufacturer and Exporter, our company is providing its customers ergonomically made Smart Soldering Machine. Designed using incorporating innovative production methods, Smart Soldering Machine can be purchased by us at market leading prices in various specifications, models and dimensions as per customers need.

Feature:

- Can Choose a particular surface handling treatment and perfect design.

- Latest bony design, first-class stroke of the same sizes.

- It is entirely supported by Windows Operating System configured user software which makes it user-friendly.

- It Alters parameters easily with progressive computer programming. It has major operation for delete point and interpolation point.

- 12" HD touch screen user interface and dynamical demonstration of moving track makes welding process more spontaneous.

- Easy operation of turning on sending tin, meets demands of soldering process and elevates efficiency of the machine.

- The anti-collision function reduces chances of product failure price (optional attribute) at the time of fortuitous collision.

- Aids the pneumatic accelerated welding capability with alternative feature to use or not to use solder joint in a cylinder.

- Licensed management unit, forbids operator to custom-make the parameters by errors.

- Flexibility in solder parameters, speed of it can be easily adjusted.

- Large band correction function with Z angle yielded, after cast repositioning divergence can be improved

- It can calculate compensate point mechanically, the angle compensation for any type of switching center.

- 04 different range types, reduces the run distance, improves manufacturing efficiency.

- The name of file can be created differently. The option of delete, edit and copy support both the languages- English and Chinese, symbols and number input too.

- File name can be independently generate, edit, copy, delete and supports Chinese or English, numbers and symbols input.

- Cycles set randomly movement is fully automatically having alert reminders

- Regular wired remote teach pendant & unlimited cable programming.

- Outfitted with energy saving LED lights which are easy to operate, welding products & simple debugging.

- Outer web input user interface having remote lifetime loose upgrades.

- Fitted with a smoke-free welding and environmental protection systems.

- 400W advanced-frequency high-power heating center, heated swiftly in order to ensure that the welding process temperature conforms to a minimum.

- Owning a lack of tin & tin block automatic sensing feature, straight security of welding products.

- Easy to operate metal button, the machine has multifaceted display; welding can be started from any location, any point can disunite welding, weld without opening from scratch.

- Axle: 5 axle+ tin solder

- Trace (XxYxZxR)mm: 500x350x100x360

- Operate speed (X/Y/Z/R): X/Y/Z:800mm/s R:180/s

- Repeat Accuracy: +/-0.02mm

- loading weight: 10Kg

- Program recording capability:unlimited

- Display:12 display screen

- operate mold: touch screen+ remote

- motor:stepper

- temperature:100C-500C

- feeding tin system: independent drive+ step motor

- min tin length: 0.01mm

- Solder Wire Dia: 0.3-1.6mm

- Voltage:220V AC/50HZ

- Air pressure: 0.4-0.8MPa, clean and dry

- Environment: 0-40 C, humidity 20%-95%

- Weight: 110kg

- Size: (WxDxH): 700x620x970

- station:two working station

Advanced Digital Control

Benefit from microcontroller-based touchscreen controls that allow for intuitive operation and precise settings. Users can easily adjust wire length and monitor soldering processes in real-time using the high-resolution LCD panel, ensuring smooth workflows in high-volume environments.

Built for Durability and Safety

Crafted from premium stainless steel and industrial alloys, the machine guarantees lasting performance. Integrated safety features such as overheat protection and an emergency stop switch safeguard operators and equipment, making it reliable for professional use at manufacturing and assembly facilities.

FAQs of Smart Soldering Machine:

Q: How does the Smart Soldering Machine automatically feed solder wire during operation?

A: The machine utilizes a built-in automatic feeding mechanism controlled by its microcontroller-based touchscreen panel. Users can program the desired wire length between 5 mm and 50 mm, and the system ensures precise feeding for consistent solder joints.Q: What benefits does the touchscreen digital control system offer?

A: The digital touchscreen control system offers intuitive navigation, customizable settings, and real-time monitoring. This allows operators to make precise adjustments efficiently, enhancing productivity and reducing the likelihood of errors during soldering.Q: When should the machines soldering speed be leveraged, and how fast can it operate?

A: The machine achieves up to 3 joints per second, making it ideal for high-throughput manufacturing, PCB assembly lines, or any environment where rapid, reliable soldering is required. Its programmable features ensure both speed and accuracy.Q: Where is the Smart Soldering Machine best applied?

A: This soldering machine is optimally used in electronics manufacturing, PCB assembly plants, and component joining operations. Its robust construction suits industrial settings requiring consistent quality and precision.Q: What process is followed for adjusting wire length?

A: Operators can set the wire length via the touchscreen panel, selecting values from 5 mm to 50 mm. The machine automatically adjusts the feed according to programmed requirements, facilitating seamless adaptation for differing job specifications.Q: How do the safety features enhance user protection?

A: Overheat protection monitors temperature levels and automatically shuts off the machine if overheating is detected. The emergency stop switch provides immediate cessation of all operations, minimizing risk and ensuring operator safety during unexpected situations.Q: What are the benefits of its material and design specifications?

A: Constructed from high-grade stainless steel and industrial alloy, the machine offers durability and corrosion resistance. Its design supports the use of nickel-plated solder wire with a flux content of 2.0% and a melting point of 230C, delivering reliable performance and clean joints for electronic applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese